Images

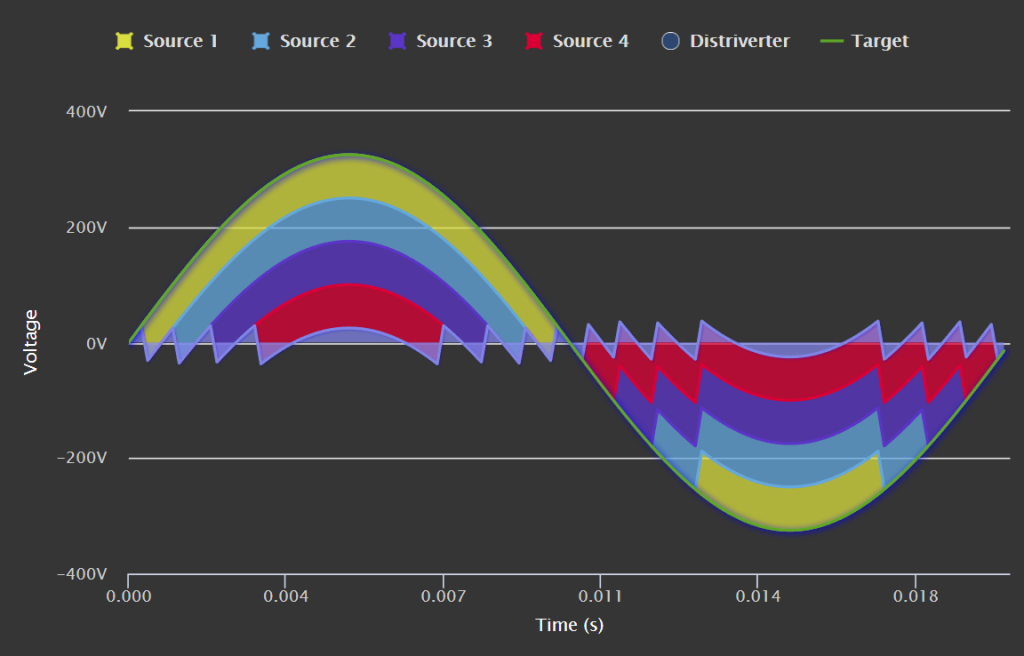

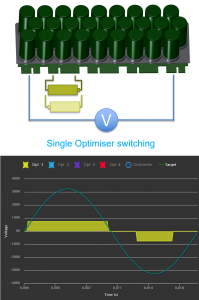

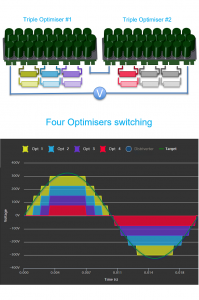

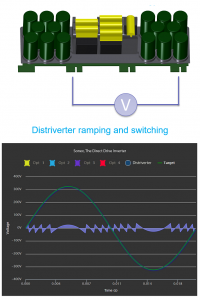

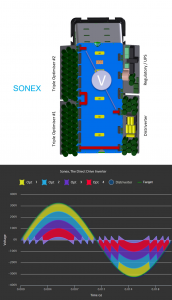

The images to the right are taken from Sunvertec’s SONEX implementation of Direct Drive Technology. Solar PV is similar but separated into individual optimisers that each have one or more MPPT inputs. The Distriverter has similar components for both Solar PV and SONEX implementations.

The Inverter Optimiser

The Inverter Optimiser, or “switcher”, is the core component of Xenos and Sonex. The Inverter Optimiser draws a controlled amount of current from its DC sources at the source’s maximum power point or moves an average current from storage devices.

For solar PV and selected SONEX implementations, a DC-DC converter moves charge between the Optimiser and power source. The Inverter Optimiser stores this charge into on-board local energy storage devices. Significantly, the DC-DC converter is extremely efficient as it typically does not alter the input voltage much at all, allowing each Inverter Optimiser to operate in excess of 99% efficiency. This gives them huge power handling for their compact size. The local energy storage devices effectively “float” a certain charge level, experiencing low ripple currents and temperatures, giving them an ultra long life.

The Distriverter

The Distriverter is at the heart of Direct Drive technology. The Distriverter creates the pure sine wave, commanding Optimisers to switch forwards or reverse to support it in creating the waveform.

When commanded by the local Distriverter, an Inverter Optimiser places its energy storage across a series connection in either a positive or negative direction via the use of very low resistance MOSFETs. After a small period, the Distriverter returns the Inverter Optimiser to its bypassed state (the default state).

By switching between these three states, positive, bypassed, and negative, Inverter Optimisers can generate a “staircase” approximation of any low frequency signal, such as a mains signal. State changes occur infrequently (< 400Hz), meaning that switching losses involved in producing this “staircase” are negligible.

Whilst each Inverter Optimiser is only a low voltage part (typically < 80V), the series connection “adds” the output of each Inverter Optimiser to the next such that high total voltages can be produced. Just as two 12V batteries produce 24V when connected in series, strings of Inverter Optimisers (and their ability to switch “positive”, “negative” or “bypassed”) are able to output controlled voltages far above that of an individual unit.